The past few weeks have seen a flurry of activity at SpaceX’s Boca Chica Launch Complex! In addition to the SN 20 prototype completing a static fire test with three of the new Raptor Vacuum 6 engines this month, the facility’s “Mechazilla” Launch Tower recently received a giant pair of steel arms. Once integrated with the ~135m (~450 ft) tower, these arms will be responsible for “catching” spent Starships and Super Heavy boosters as they return to Earth.

The Tower will also prepare missions by stacking first stage boosters with Starships and refueling these elements for the next launch. In this respect, the Launch Tower is a crucial piece of the Orbital Launch Site (OLS) architecture that Elon Musk has planned for Boca Chica. Once the Starship completes its Orbital Flight Test (which could happen soon!), Boca Chica will become a spaceflight hub where launches and retrievals are conducted regularly.

In addition to the Launch Tower, several elements will be added to the OLS as part of its Ground Support Equipment (GSE) site. This will likely include additional fuel tanks, water tanks, pipelines, a pumping station, and other amenities. Together, the Launch Tower and the GSE will enable SpaceX to launch, retrieve, refuel, and relaunch its vehicles, ensuring rapid reusability and minimized turnaround time.

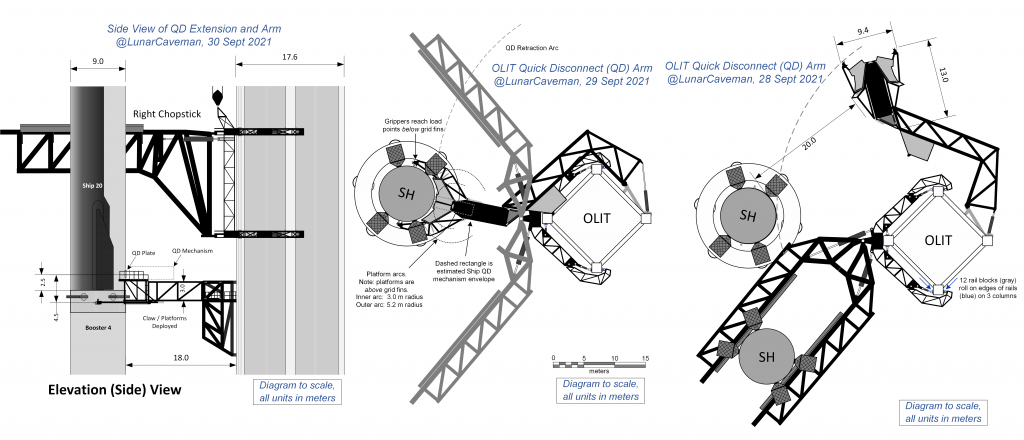

These giant steel arms, nicknamed the “chopsticks” by the crews at Boca Chica, are mounted to a carriage-like structure. The Tower, meanwhile, is equipped with rails that have a series of skates, which the ground crews attached the carriage to using a series of large pins. Once the arms are integrated, they will be paired with a third Quick Disconnect (QD) arm that will stabilize boosters whenever they are in the process of being stacked with the Starship.

The QD arm is also tasked with distributing power, commlinks, and ~1.088 million kg (2.4 million lbs; 1200 US tons) of cryogenically-cooled propellant to the upper stage. This was the first component installed aboard the Launch Tower, which took place in late August, about a month after the crews finished stacking the Tower. Around the same time, construction began on the carriage-like structure and the two giant arms, which took about three months to complete.

The integration of the QD arm with the Launch Tower began on Oct. 6th, when the ground crews moved the carriage into a vertical position and reoriented the “chopsticks” so they were angled the right way. By Oct. 20th, they completed the first step of installing the carriage and arms onto the rail skates using the facility’s largest crane. Twelve connections need to be made in total before the catch arms will be a part of the Tower without the help of a crane.

However, before the catch arms can perform on their own, the ground crews also need to finish installing the hundreds of meters of steel cable that will support the carriage and arms and (with the help of a system of pulleys) lift it up and down. They also need to finish work on the giant “cable carrier” that will connect the structure to the ground and control systems.

In these illustrations of the Launch Tower at Boca Chica, we see how the “catch arms,” QD, and carriage facilitate rapid reusability. Credit: Bill Adsit/@LunarCaveman

In these illustrations of the Launch Tower at Boca Chica, we see how the “catch arms,” QD, and carriage facilitate rapid reusability. Credit: Bill Adsit/@LunarCaveman

In other news, Elon Musk recently divulged that the long-awaited Orbital Flight Test could take place sometime in November. Musk shared the news via Twitter (as always), indicating that the test could happen “if all goes well” and pending approval by the Federal Aviation Administration (FAA). This test will see the SN 20 prototype fly to an altitude of 200 km (124 mi), then make a soft touchdown on the landing pad.

Once complete, this flight will validate the Starship as an orbital vehicle and demonstrate its ability to return from space safely. For this reason, the SN 20 is the first prototype to be outfitted with heat-resistant tiles to protect the prototype’s stainless steel hull from the scorching heat it will encounter during atmospheric re-entry. This update came a day after the SN 20 prototype successfully concluded the first static fire test of the Vacuum Raptor Engine 6.

These engines have a larger nozzle than the Raptor Engines optimized for sea level, which gives them improved performance in the airless environment of space. The SN 20 will also have three of these Raptor engines to ensure that it can make a controlled landing once it’s returned to Earth’s atmosphere. Once this orbital flight is complete, the Starship will officially be ready to move into commercial flights.

These developments are timely, given that Musk hopes to send the Starship on its inaugural mission by 2023. This mission is being financed by Japanese billionaire, entrepreneur, and art collector Yusaku Maezawa and will see a crew of eight artists making a circumlunar flight (the purpose of which will be to inspire art and raise SpaceX’s profile). Musk has also indicated that his company plans to send uncrewed missions to Mars by 2024, followed by crewed missions by 2026.

That’s a tall order, for sure. And such a plan requires a robust testing schedule! But if this latest news from South Texas is any indication, SpaceX might make those deadlines!

Further Reading: Teslarati