Space News & Blog Articles

‘We nailed it!’ Webb clears major hurdle with full sunshade deployment

Artist’s illustration of the James Webb Space Telescope, as it appeared Jan. 4 after sunshield tensioning. Credit: NASA

Artist’s illustration of the James Webb Space Telescope, as it appeared Jan. 4 after sunshield tensioning. Credit: NASA

The final layers of the James Webb Space Telescope’s sunshade were robotically pulled taut with a system of motors, cables, and pulleys Tuesday, clearing a major milestone before unfolding mirrors to collect light from the oldest galaxies in the universe.

“We nailed it,” said Alphonso Stewart, Webb’s deployment systems engineer at NASA’s Goddard Space Flight Center.

The achievement means NASA has retired around three-quarters of Webb’s 344 mission-critical single-point failures, devices and components that have to work for the observatory to complete its mission.

“Today was a big day, obviously, for us,” said James Cooper, Webb’s sunshield manager at NASA. “We finished tensioning the last two layers of the sunshield, so that completes the sunshield deployment steps.”

The sunshade’s deployment and tensioning plunged the Webb telescope’s mirrors and instruments into eternal darkness, allowing the sensors to begin cooling down to minus 388 degrees Fahrenheit (minus 233 degrees Celsius), or 40 degrees above absolute zero.

The cold temperatures are necessary for Webb’s science instruments to register the faint infrared light, or heat signature, from the first galaxies and stars that formed after the Big Bang. Webb is designed to peer back to within 100 million to 200 million years of the violent birth of the universe, which occurred some 13.8 billion years ago.

The Webb telescope unfurled its sunshield into its distinctive diamond shape New Year’s Eve, guided by two mid-booms that extended from each side of the spacecraft. After pausing deployment steps over the weekend to resolve minor concerns about Webb’s solar panel power levels and motor temperatures, mission controllers on Monday started critical work to begin tensioning the five-layer thermal barrier.

Beginning with the outermost, sun-facing membrane, the first three layers of the sunshade were tensioned Monday. Mission controllers at the Space Telescope Science Institute in Baltimore, Maryland, resumed tensioning operations Tuesday morning.

Six motors positioned at tension points around the perimeter of the sunshield pulled on cables to tug each layer into its final fully taut position. Ground teams announced the final layer was tensioned at 11:59 a.m. EST (1659 GMT) Tuesday, prompting applause in the control center in Baltimore.

“MOM, I can confirm the final latch signature … which indicates that all five layers are fully tensioned,” said a member of the Webb control team to the Mission Operations Manager, Carl Starr.

Starr replied: “Significant milestone accomplished. Job well done, sunshield team. Job well done.”

Sunshield tensioning is complete!

The thermal shade on the James Webb Space Telescope has been fully tightened in its diamond shape, stretching out to the size of a tennis court.

This completes a crucial phase in preparing Webb for science operations.https://t.co/phLEclX8tM pic.twitter.com/X1OqY4ZwBc

— Spaceflight Now (@SpaceflightNow) January 4, 2022

“This is the first time anyone has ever attempted to put a telescope this large into space,” said Thomas Zurbuchen, associate administrator for NASA’s science mission directorate. “Webb required not only careful assembly but also careful deployments. The success of its most challenging deployment – the sunshield – is an incredible testament to the human ingenuity and engineering skill that will enable Webb to accomplish its science goals.”

The sunshield was widely considered by Webb engineers and astronomers to be the most difficult part of the mission. And that’s saying something, since Webb needs dozens of deployment steps to transform itself from launch configuration to a science-ready telescope.

NASA said Webb’s sunshield deployment and tensioning involved 139 of the mission’s 178 release mechanisms, 70 hinge assemblies, and eight deployment motors, including six for the tensioning and two for the boom extensions. There were also roughly 400 pulleys and 90 individual cables totaling around a quarter-mile in length.

The sunshield measures 69.5 feet by 46.5 feet (21.2 meters by 14.2 meters), and is designed to provide a nearly 600-degree thermal gradient between the hot spacecraft, which needs to aim its solar panel toward the sun, and the cold telescope mirrors and instruments. It has five layers, each as thin as a human hair, made of a material called kapton, supplied by DuPont, and treated with shiny aluminum. The two outermost layers have an additional purple-hued silicon coating to aid in reflectivity.

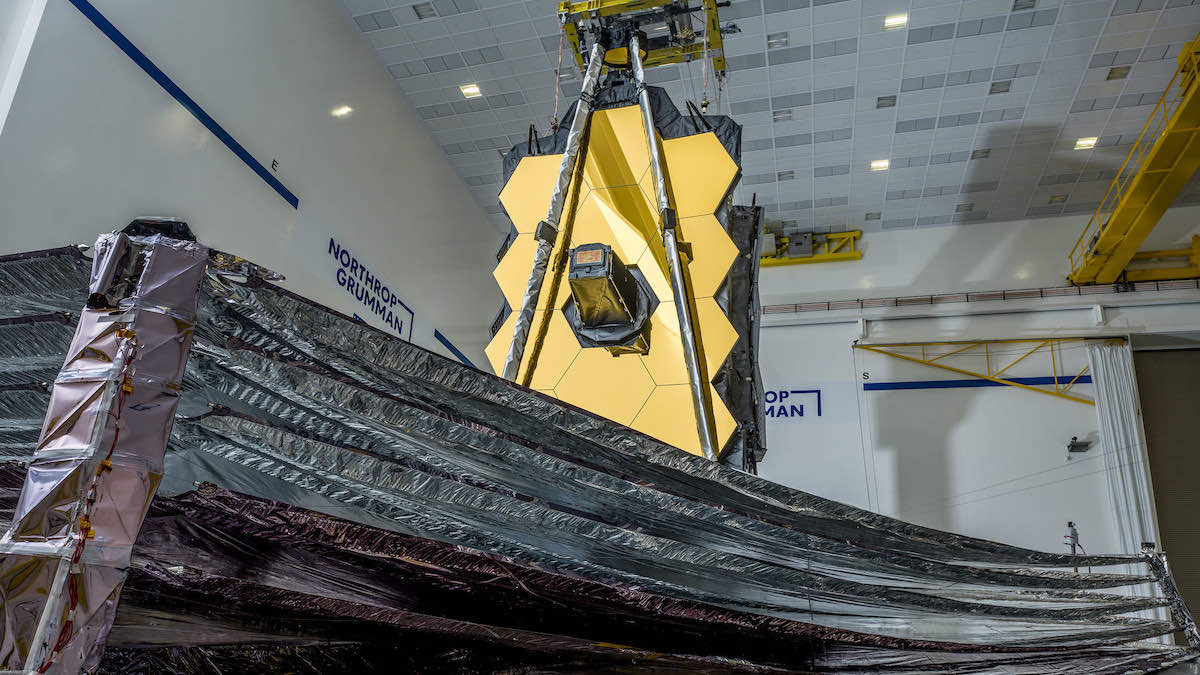

The James Webb Space Telescope’s five-layer sunshield, seen here during ground testing at Northrop Grumman’s factory in Redondo Beach, California. Credit: NASA/Chris Gunn

The James Webb Space Telescope’s five-layer sunshield, seen here during ground testing at Northrop Grumman’s factory in Redondo Beach, California. Credit: NASA/Chris Gunn

The tensioning separated each of the five ultra-thin membranes, spacing them a few inches at the center and a few feet at the outermost edges. The tapered spacing helps allow heat from the sun to reflect between the layers, and eventually radiate back into space.

The design allows Webb to passively cool its telescope, providing protection equivalent to a sunscreen with a rating of more than SFP 1 million.

Webb doesn’t have any cameras on-board to monitor its complex deployment sequence — including them could have impeded the observatory’s cool-down, officials said — so ground teams watch for telemetry signals to track the mission’s progress.

Engineers knew how many revolutions of each motor to expect, and what motor currents to anticipate before each layer was latched into place, Cooper said.

“So tracking all of those parameters give us a good indication that it went as far as we thought it would, it pulled as hard as we thought it would, therefore, it pulled in the right place,” he said. “That’s kind of the way we make those connections without any images.”

“What we’re seeing is really the heartbeat of this mechanism, and this mechanism is very intricate and very complex, but because of that, we’re able to glean so much about the hardware position, (and) the hardware resistance, from the motor telemetry,” said Hilary Stock, a sunshield deployment specialist at Northrop Grumman, NASA’s prime contractor for Webb. “So we feel very good looking at these signatures, seeing the drops in current, and understanding that that’s related to a layer latched in the correct position, and everything lined up today.”

The movement of spring mechanisms in the tensioning system gave engineers indications about the geometry and position of each layer, and that’s how ground teams were able to confirm each membrane is properly separated from the there layers, Stock said.

With the completion of the sunshield tensioning, the motors, cables, and pulleys won’t be used again.

“They’ve served their purpose, and now they’re along for the ride,” Stock said.

The Webb telescope launched Dec. 25 aboard a European Ariane 5 rocket, and performed well as it unfolded its solar array, high-gain communications antenna, and two large pallet structures that held the sunshade layers for the ride to space.

Webb extended a tower assembly last week to provide distance between the telescope’s mirrors and instruments, and the much hotter spacecraft element.

Ground teams uplinked commands for Webb to roll off covers to reveal the sunshield membranes Thursday, then extended two mid-booms out each side of the spacecraft Friday, pulling out the five sunshade layers like sheets on a bed.

That set the stage for sunshield tensioning Monday and Tuesday, following a two-day stand-down over the weekend.

“I think that the sunshield deployment certainly was the most complex (Webb deployment) in terms of moving parts having to all work in harmony, systems that interplay with each other, structures and mechanisms and cables,” Cooper said.

What’s left for Webb to complete its transformation into a working telescope are more “conventional” deployments using hinges and rigid structures, rather than the flimsy sunshade layers, Cooper said.

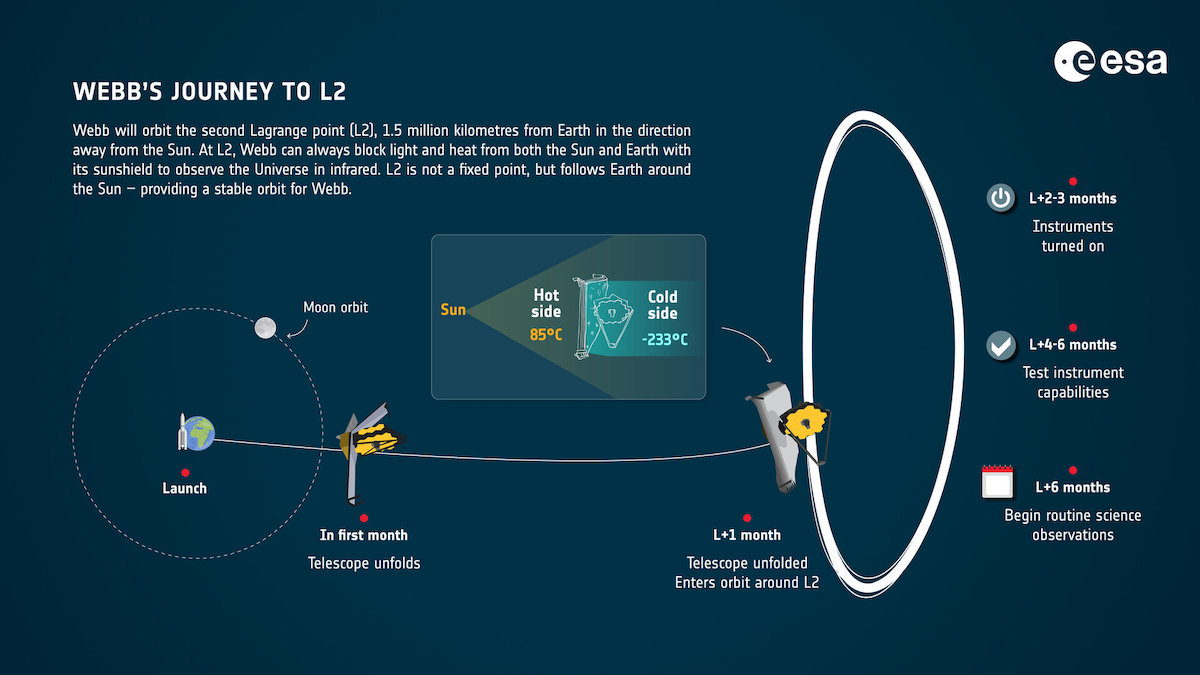

This infographic illustrates Webb’s journey to L2. Credit: ESA

This infographic illustrates Webb’s journey to L2. Credit: ESA

Ground teams will turn their attention to unfolding Webb’s huge primary mirror to its full 21.3-foot-wide (6.5-meter) diameter, the biggest telescope ever sent into space. A secondary mirror, mounted on a tripod-like boom apparatus, also needs to move into place to reflect light into Webb’s instrument module, and ultimately onto detector arrays to make images and spectral measurements.

“Half my mind is going, ‘Woo hoo!,’ and half my mind is going, ‘We’ve got to get that secondary mirror out,'” said Keith Parrish, NASA’s commissioning manager for Webb, following Tuesday’s sunshield tensioning.

The secondary mirror deployment will occur first. That crucial event is slated for Wednesday, followed by folding of the port and starboard mirror wings into place at the end of the week.

Webb is cruising toward its operations post in a halo-like orbit around the L2 Lagrange point, a gravitational balance location nearly a million miles (1.5 million kilometers) from Earth. Webb’s arrival in that orbit is expected around Jan. 23, followed by five more months of instrument activations, optical focusing, and other calibration work before the science mission begins.

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.

When you subscribe to the SpaceZE News Feed, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.